Description

Apex Machine has wide range of product and production line solutions.

We produce our gasket rubber production lines with different capacity and raw material options according to final product of our customers and working raw material.

Seal Strip | Gasket Extrusion Machine General Details,

Easy to use with touchscreen control panel

Long using life and low using cost for gasket extrusion

Gasket extrusion Gear-Box with oil pump indicator

Second or thirth raw material option with CO-Extruders

Different raw material options on gasket extrusion lines

Hard-Soft raw material options on gasket extrusion line

Grinded gear wheels with hardened 8620 steel

Standard extrusion screw height center 1100 mm

Synronisation system for complete gasket extrusion line

Easy changeable extrusion and gasket mold system

Speed adjusting with inverter control on complete extrusion line

Automatic gear lubricant oil

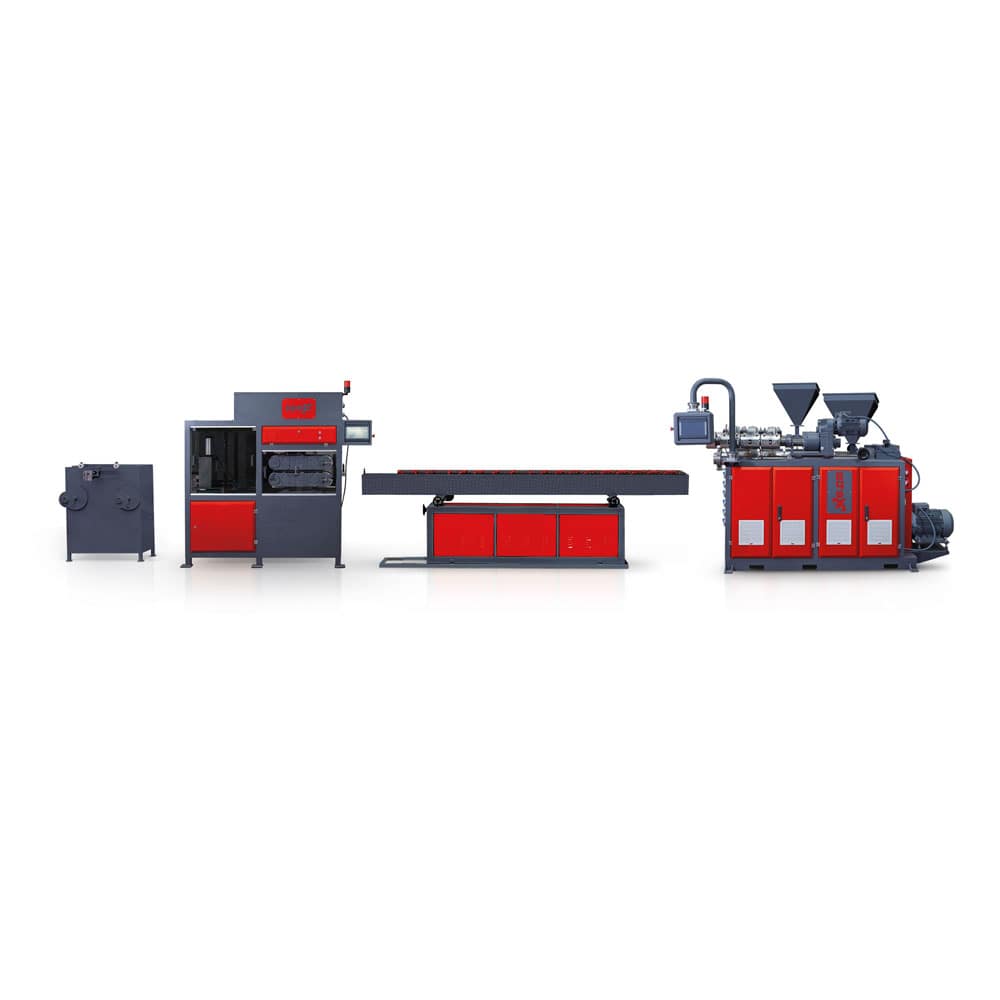

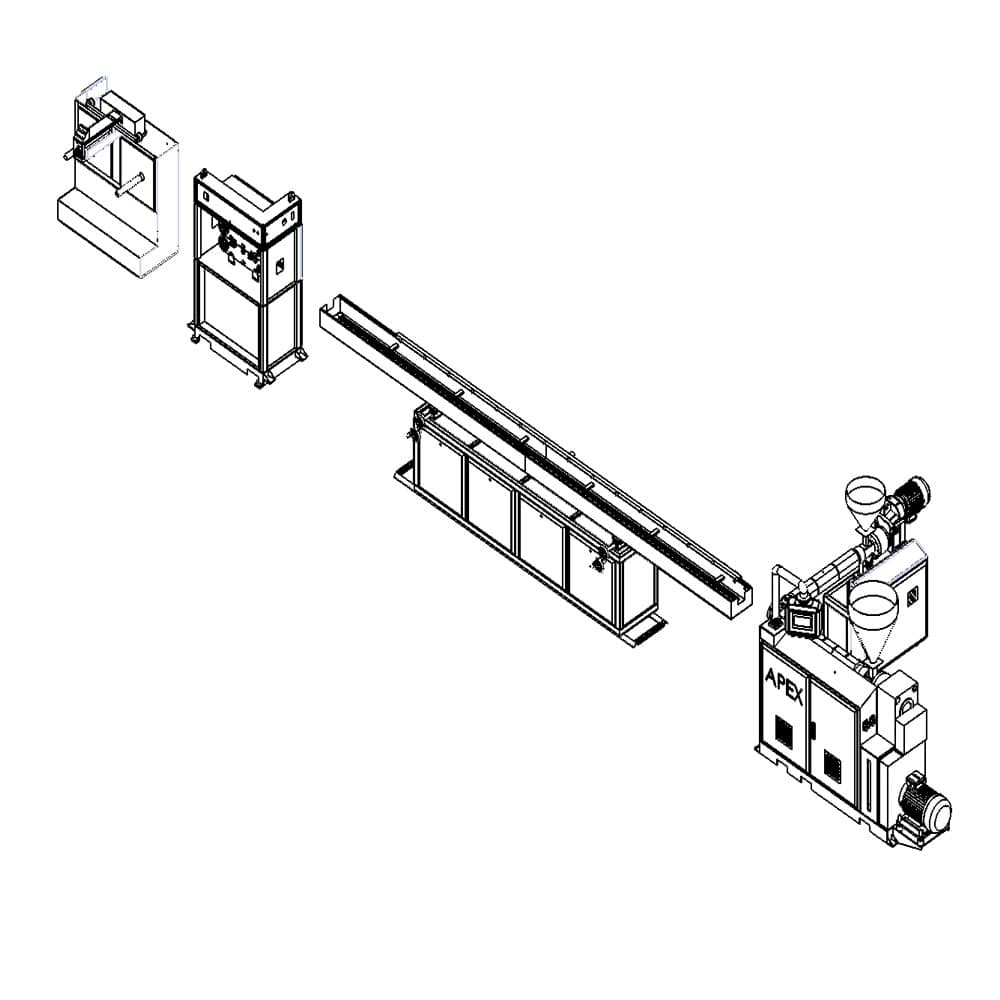

Gasket Production Line

Different gasket rubber production line capacity

Different gasket rubber production line raw material combinations

Different gasket rubber production line lenght as to product type

Extrusion screw material from German DIN 8550 Nitrated Steel

Extrusion screw hardness level with 65-70 HRC Rockwell

We have the best solution for our customers for reaching maximum productivity on gasket exturusion lines.

Our extrusion line can work with raw material PVC, PP, PE, TPO, TPE, TPU, EVA, PET, PS, WPC, ABS, HDPE, PC, TPR, PEX, PA, etc.

Why Apex Machine ?

– With best quality extrusion screw, long using life

– Easy to use extrusion software

– Wide product range on extrusion industry

– Complete extrusion line solutions

– Different extrusion line design options as to customer demands

– DIN 8550 Nitrated Extrusion Screw Steel

Reviews

There are no reviews yet.