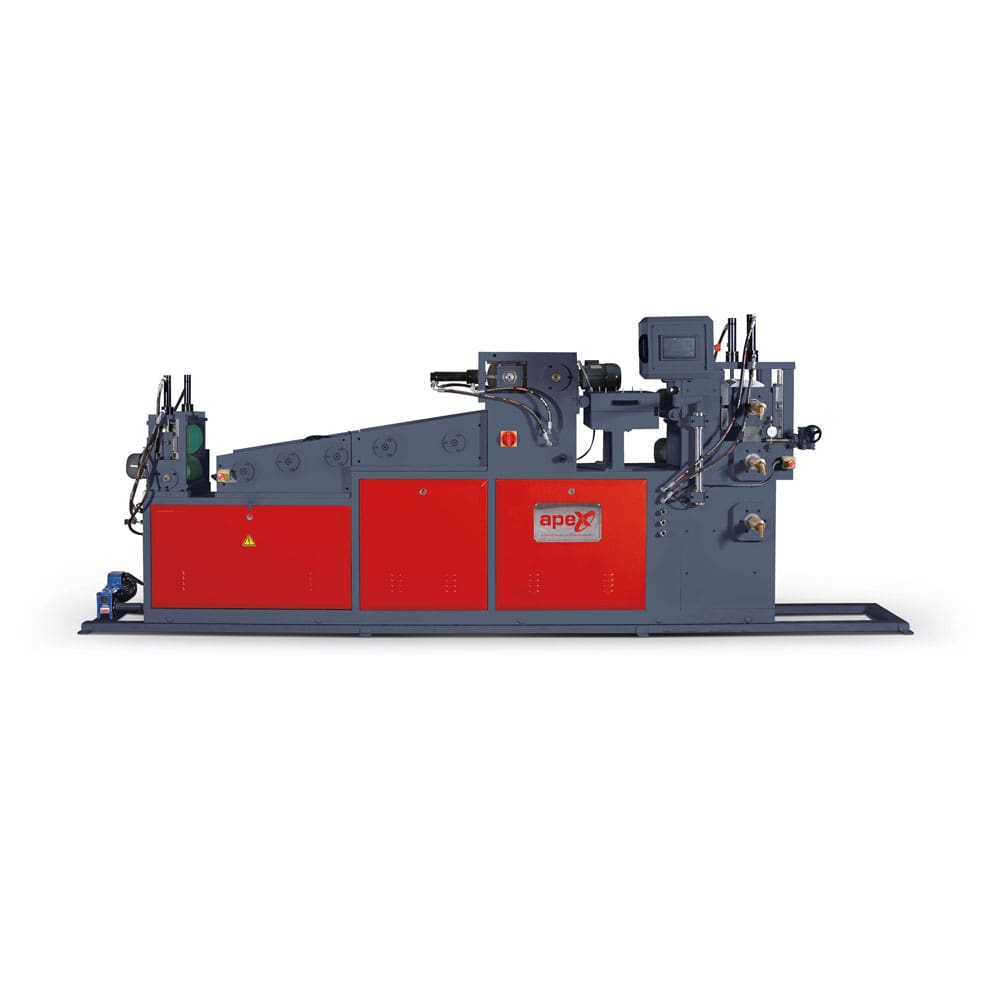

Description

Apex Machine has wide range of product and production line solutions.

We produce our plastic calendering machines with different working width, thickness, calendering capacity according to final product of our customers, working raw material and our customer’s demands.

Plastic Calendering Machine General Details,

Easy to connect with extrusion line

Calender machine can work separately or with extrusion line

Long using life and low using cost on calender machine

Standard working height center 1100 mm on calender machine

Synchronisation system on calender with complete extrusion line

Speed adjusting on calender with inverter control

Different working capacity on calendering machine

Color transfering stencil roller on color printer (Steel)

Hydraulic movement with automation strengthen

Working width range from 200 mm to 2600 mm

Working thickness range from 0,20 mm to 8 mm

Double layer heating or cooling

Warm transfering as optional

Plastic Calendering Machine Properties

Hydraulic calender pressure system

Stable middle and down calender rollers

Inductioned and grinded calender rollers

Chrom coated surface 300 microns

Automatic thickness stabilization system

Linear thickness adjustment guides

Movable upper rollers on calendering machine

Movable systems with linear guides

We have the best solution for our customers for reaching maximum productivity.

Our calendering machines can work with raw material PVC, PP, PE, TPO, TPE, TPU, EVA, PET, PS, WPC, ABS, HDPE, PC, TPR, PEX, PA, etc.

Why Apex Machine ?

– Good quality calendering machine with good price

– Easy to use calender machine with other extrusions

– Wide product range on extrusion industry

– Complete extrusion line with calendering machine

– Different calendering machine design options as to customer demands

– DIN 8550 Nitrated Extrusion Screw Steel

Reviews

There are no reviews yet.